12 Feb 2025

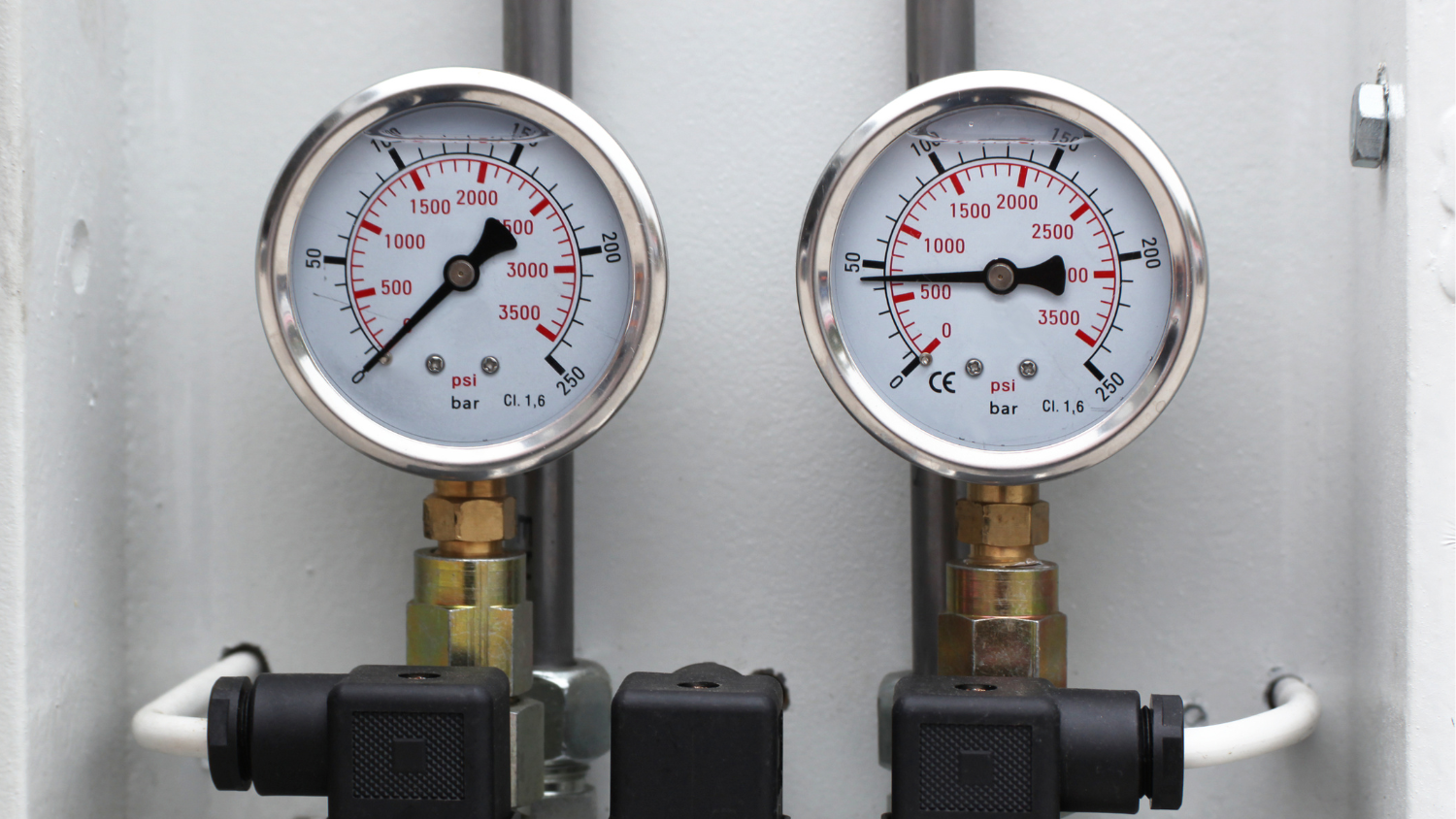

Why isn't the needle on my glycerine-filled pressure gauge at zero?

We wouldn't be surprised to learn that you've already noticed that the needle on your glycerine-filled pressure gauge isn't at zero. We're sure you've wondered about the origin and cause of this situation, and perhaps you've found the answer!

Since it's a common question, we've taken a closer look.

The role of glycerine in a pressure gauge

Before going any further, let's remember that the glycerine in a pressure gauge has a specific purpose: to dampen vibrations and shocks to ensure accurate readings and prolong the life of the device. This viscous substance acts as a damping fluid, reducing unwanted needle movements.

However, the presence of glycerine introduces an additional challenge: the gauge's internal pressure can vary according to ambient temperature.

Why does internal pressure change?

The change in internal pressure is mainly due to two factors:

- Temperature variations : When the temperature rises, the glycerine and air inside the manometer expand, increasing the internal pressure. Conversely, a drop in temperature causes these elements to contract, reducing internal pressure.

- Atmospheric pressure : Variations in external atmospheric pressure also influence the pressure gauge, particularly if the compensation plug is not handled correctly.

These variations in internal pressure can cause the needle to move, even when no pressure is applied to the device.

The solution

To equalize the internal pressure with the external pressure, simply lift the compensation plug located on the top or rear of the manometer. This plug is designed to allow air exchange between the inside and outside of the unit, while preventing glycerine leaks.

How do I do it?

- Identify the cap on your pressure gauge. It's often rubber or plastic, with a tab or small opening.

- Gently lift the plug to let air in or out, as required.

- Once the needle returns to zero, reposition the plug to close the system.

Some precautions to be taken

- Extreme temperatures: If your manometer is exposed to very high or very low temperatures, it is important to check the condition of the pointer regularly, and to adjust the pressure if necessary.

- Correct use: Do not force the cap. Handle it with care to avoid damaging the manometer or causing glycerine leaks.

A simple solution

If the needle on your glycerine-filled pressure gauge isn't at zero, it's not usually a device fault. It simply reflects an imbalance between internal and external pressure, often caused by temperature variations. Raising the compensation plug will restore this balance and ensure an accurate reading.

If you require maintenance or calibration of your pressure gauge, please do not hesitate to contact us. Our experts at Chevrier Instruments Inc. are here to help!