Description

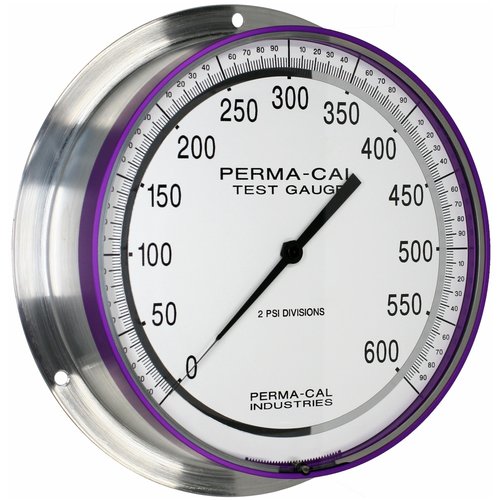

CLEARLY IDENTIFIES SKYDROL

The purple aluminum ring (Hard Anodize/Type 3, Class 2) clearly identifies the use of Skydrol without the risk of corrosion or discoloration.

APPLICATIONS

Ideal for use in aerospace hydraulic test facilities and fluid control manufacturing facilities where Skydrol is used.

The product is designed for highly corrosive chemicals and can be customized to designate a use other than Skydrol.

ACCURACY

- ±0.25% F.S. (Grade 3A) - Series 10

- ±0.5% F.S. (grade 2A) - series 11

- ±0.5% F.S. at mid-scale / ±1.0% F.S. - 12 Series

For more details, see the accuracy specifications page

RANGE AVAILABILITY

- Vacuum - 15,000 psi (or equivalent)

- Units: psi, bar, kPa, MPa, kg/cm², inHg, mmHg

- Types: Single or dual scale, vacuum and combination

Customization possible (range, units, logo, etc.)

See Dial Availability Chart for Standard Range List

Ordering Code

OPERATING TEMPERATURE

Operating Temperature Fluid:

- ABS: -65°F to 250°F

- GFN and Metal: -65°F to 600°F

Ambient Temperature:

- ABS: -65°F to 190°F

- GFN and Metal: -65°F to 400°F

OTHER SPECIFICATIONS

- Burst Pressure: 500% F.S. pressure or 25,000 psi

- Test Pressure (overpressure without calibration offset):

- 150% F.S. for gauges ≤ 5,000 psi or equivalent

- 125% of F.S. for gauges > 5,000 psi or equivalent

- Internal pointer dampening (reduces pointer float)

HOUSINGS

Materials:

- Aluminum or stainless steel housing

- Aluminum ring (hard anodized purple type 3, class 2)

Sizes, Types and Colors:

- 3.5", 4.5", 8.5"

- Flange back

- Flangeless housing

- Unpainted housing, purple ring

Solid front housing design

Customization available (range, units, logo, etc.)

QUALITY MATERIALS

Contact Parts:

- Inconel X-750

- 300 Series Stainless Steel

- Silver Brazing (Nickel Brazing Available)

Connection Material

- Standard 316 Stainless Steel (Monel Available)

Window

- Tempered glass (increases heat tolerance)

Dial

- Stainless steel material, powder coated finish

- White background, black markings, black pointer